Dental implant torque wrench error: Solving the problem

Clinicians strive to provide the very best care for their patients. However, issues can arise that require a change in practice. One such example is the problem of implant screw loosening, which has a reported incidence of 5%–12% over a five-year period.1,2

The most common cause of screw loosening is the initial screw-tightening torque. All screws are designed to work within a specific tightening (torque) range—a range that they should never be torqued below (too loose) or above (too tight).3

Manufacturers specify an optimum torque value. To apply target torque, specialized instruments in the form of torque wrenches are required. Generally, these instruments come in two forms: electronic and manual. Because the electronic versions are deemed less accurate and less precise,4 manual versions are preferred.

But manual wrenches have deficiencies that must be accounted for as well. The toggle- or friction-style devices must be meticulously maintained.5 The cantilever beam wrench is far more reliable, but it has a major problem in that it cannot record maximum or peak values produced; and even more of an issue is the problem of measurement read error (MRE).6

You might also be interested in …

My dental implant screw loosened: Did I miss something?

MRE occurs because of viewing angle and parallax. Whenever the cantilever beam cannot be viewed directly at 90 degrees, an under- or overread will occur. This translates into either undertorquing or overtorquing the screw, neither of which is desirable. Further, both overtorquing and undertorquing can lead to premature screw joint failure.

A solution for torquing just the right amount

To overcome this issue, a simple, yet highly effective device has been developed: the SmartMarker (ImplantWise). The SmartMarker has two major advantages:

- It counteracts viewing issues with parallax, so it resolves MRE.

- It provides a peak value reading that allows the operator to confirm the screw is not too loose or too tight.

A comparison group of photographs highlights the issue, with and without the SmartMarker, when the operator is in any position other than with a 90-degree view of the torque wrench (figures 1-3).

How to use the SmartMaker

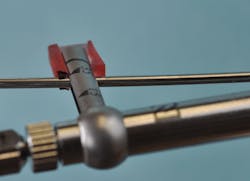

Slide the SmartMaker onto the cantilever beam (figure 4). As the wrench is activated, the marker slides along the beam to indicate the torque being applied. The marker is designed to allow easy reading irrespective of the viewing angle (figure 5). The friction clip of the SmartMarker holds the position of the maximum torque, so when the wrench is finally removed, the operator can confirm the peak torque value.

Author’s note: The SmartMarker is available from implantwisedental.com.

Disclosure: Dr. Chandur Wadhwani and Georgina Frantz serve on the board of directors of ImplantWise LLC.

Editor’s note: This article originally appeared in Perio-Implant Advisory, a chairside resource for dentists and hygienists that focuses on periodontal- and implant-related issues. Read more articles and subscribe to the newsletter.

References

- Goodacre BJ, Goodacre SE, Goodacre CJ. Prosthetic complications with implant prosthesis (2001-2017). Eur J Oral Implantol. 2018;11(Suppl 1):S27-S36.

- Katsavochristou A, Koumoulis D. Incidence of abutment screw failure of single or splinted implant prostheses: a review and update on current clinical status. J Oral Rehabil. 2019;46(8):776-786. doi:10.1111/joor.12817

- Bickford J. An Introduction to the Design and Behavior of Bolted Joints. 3rd ed. Taylor & Francis Group; 1995.

- Albayrak H, Gumus HO, Tursun F, Kocaagaoglu HH, Kilinc HI. Accuracy of torque limiting devices: a comparative evaluation. J Prosthet Dent. 2017;117(1):81-86. doi:10.1016/j.prosdent.2016.07.005

- Gutierrez, Nicholls JI, Libman WJ, Butson TJ. Accuracy of the implant torque wrench following time in clinical service. Int J Prosthodont. 1997;10(6):562-567.

- Wadhwani CPK, O’Brien R, Rosen PS, Chung KH. Effect of viewing angles on measurement errors when using an implant cantilever beam torque-limiting device J Prosthet Dent. 2022;S0022-3913(21):00656-9. doi:10.1016/j.prosdent.2021.11.022

About the Author

Chandur P.K. Wadhwani, BDS, MSD

Chandur P.K. Wadhwani, BDS, MSD, is in private practice limited to prosthodontics in Bellevue, Washington. He is an affiliate assistant professor in the department of restorative dentistry at the University of Washington School of Dentistry in Seattle, Washington; associate professor at the University of Oregon Health Science University in Portland, Oregon; and assistant professor of the advanced education program in prosthodontics at Loma Linda University in Loma Linda, California.

Updated April 21, 2023